Unique, one-of-a-kind designs you won’t find anywhere else, crafted with the woods of your choice.

STEP 1

You choose what model cigar humidor you want

STEP 2

You choose the wood species you want

STEP 3

Your cigar humidor is built from scratch

STEP 4

Your humidor is usually shipped to you in 4-6 weeks

Choosing the model

Whether you’re wanting a desktop cigar humidor for your home or a travel cigar humidor to take with you, we’ve got you covered.

We currently offer four different models of cigar humidors to choose from:

- The Lancelot – 65-75ct. Desktop Cigar Humidor

- The Merlin – 25-35ct. Desktop Cigar Humidor

- The Galahad – 8ct. Travel Cigar Humidor

- The Camelot – 4ct. Travel Cigar Humidor

Each model has a corresponding base price. You choose which cigar humidor fits your needs and budget the best.

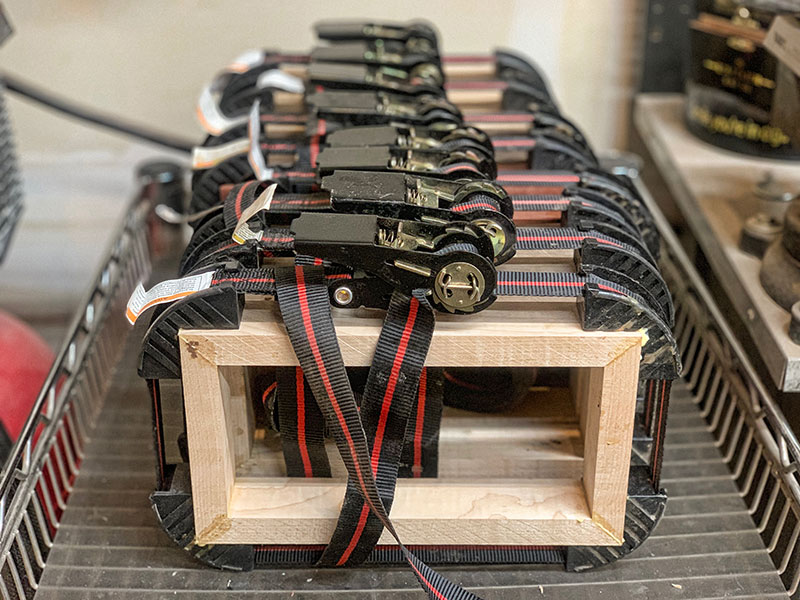

Choosing the woods

We have 34+ different species of woods to choose from ranging from common domestic woods to super rare exotic woods.

If you’re wanting a cigar humidor to match the woods in your home, or wanting something unique that pops, we can make it happen. Generally speaking, the domestic woods can keep the humidor closer to the base price, whereas crazy exotic woods will make it more expensive.

WE DON’T USE VENEERS! We only use solid lumber to craft your new cigar humidor.

Handcrafting your humidor

Your cigar humidor is handcrafted out of the woods you chose.

Sit back and relax as your humidor comes to life. We start with only the finest raw materials and mill/machine everything in-house. If you’d like to see progress pictures along the way, that’s not a problem.

Shipping your humidor

Your cigar humidor is usually shipped in 4-6 weeks.

Under normal circumstances, your cigar humidor is handcrafted in roughly 4-6 weeks. Depending on the time of the year and current workload, this can vary a bit but usually this holds pretty true. If you have a specific date-in-hand in mind, please let us know.

Every humidor is fully wrapped in layers of bubble wrap and is shipped fully-insured. Better to be safe than sorry.

Start building your new humidor

Choose from a variety of domestic and exotic woods